Осредняющая напорная трубка KTM Дельтапаскаль ®

Проекты по сокращению затрат по расходу электроэнергии и увеличению ресурса насосного оборудования. Учет пара, горячих жидкостей и сверхгорячих дымовых выбросов

Преимущества:

- Экономия 5-15% на расходах на электроэнергию при замене сужающих устройств на трубку пито за счет уменьшения перепада давления с 20-30 % до 5-8 %;

- Увеличение срока службы и ресурса паровой турбины или насоса на 20% за счет сокращения входящего давления;

- Сокращение расходов в 4 раза на демонтаж/монтаж расходомера, поверку, транспортные расходы, обменный фонд, отсутствие затрат на ремонт;

- Интегрированный вычислитель во взрывозащищенной оболочке, готовый к вычислениям объема без дополнительного оборудования;

- Монтаж/демонтаж без остановки технологического процесса;

- Имитационная поверка;

- Компенсация расхода по температуре и давлению;

- Учет на газоходах сложной формы;

- Учет газов высокой температуры до +710 °С до 25 МПа;

- Учет выбросов в атмосферу на трубопроводах диаметрами до 15 м;

- МПИ – 4 года, срок службы – 18 лет.

МЕТРОЛОГИЧЕСКИЕ И ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

|

Наименование параметра |

Значение параметра |

|

Диаметр условного прохода трубопровода DN, мм |

от 25 до 2950 |

|

Материал измерительной части |

AISI 316L / 03Х17Н14М3 |

|

Диапазон измерений объёмного расхода, м³/ч: |

|

|

— жидкости |

от 0,35 до 358000 |

|

— газа |

от 0,7 до 4,8∙106 |

|

— пара |

от 0,7 до 6,9∙106 |

|

Температура рабочей среды, ºС |

от — 196 до + 710 |

|

Избыточное давление рабочей среды, МПа |

до 25 |

|

Максимальный перепад давления, кПа |

300 |

|

Относительная погрешность измерения, % |

|

|

— объёмного и массового расхода |

±0,5; ±0,7; ±1,0; ±1,5 |

|

— объёмного и массового расхода при имитационной поверке |

±2,0 |

|

Межповерочный интервал, лет |

4 |

|

Температура окружающей среды, °С |

от — 40 до + 60 |

|

Степень защиты от проникновения твердых предметов и воды по ГОСТ 14254 (IEC 60529) |

IP66/67 |

|

Маркировка взрывозащиты БОИ |

1Ex db e [ia Ga] IIC T6 Gb X |

|

Выводы и интерфейсы: |

— частотный (сигнал периода времени TPS)/импульсный выход; — аналоговый конфигурируемый выход токовая петля с поддержкой HART; — RS-485 с поддержкой Modbus RTU и Modbus ASCII; — Ethernet с поддержкой Modbus TCP; — аналоговый вход для датчиков температуры и давления, токовая петля с поддержкой HART |

|

Напряжение питания постоянного тока, В |

от 12 до 30 |

|

Потребляемая мощность, Вт, не более |

15 |

|

Срок средней наработки на отказ, ч, не менее |

100 000 |

|

Срок службы, лет |

18 |

|

Наименование |

Внешний вид |

Давление |

Температура |

Диаметр |

|

По установке на трубопровод |

||||

|

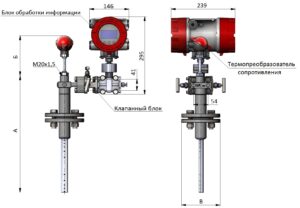

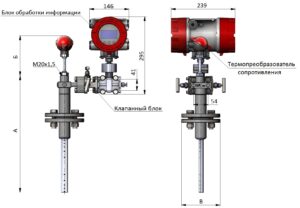

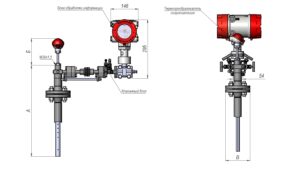

Фланцевое |

|

до 25 МПа |

до +710 °С |

До 2 950 мм (опционально до 15 000 мм) |

|

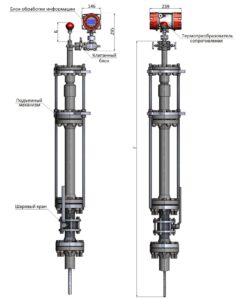

Retractable |

|

до 10 МПа |

до +500 °С |

до 1200 мм |

|

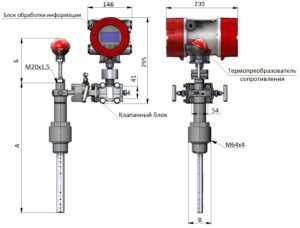

Rotate-lock |

|

до 10 МПа |

до +500 °С |

до 2950 мм |

|

По расположению БОИ |

||||

|

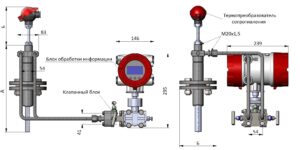

Интегральное |

|

до 25 МПа |

до +120 °С |

до 2 950 мм (опционально до 15 000 мм) |

|

Интегральное с разделителями (охладителями сред) |

|

до +300 °С |

||

|

Раздельное |

|

до +710 °С |

||

ВАРИАНТЫ РАЗМЕРОВ ИЗМЕРИТЕЛЬНОГО ЭЛЕМЕНТА

|

Ширина измерительного элемента |

Диаметр трубопровода |

Диаметр патрубка для монтажа |

|

8 мм |

От 25 до 60 мм |

15 мм |

|

12 мм |

От 50 до 150 мм |

20 мм |

|

25 мм |

От 100 до 800 мм |

32 мм |

|

44мм |

от 400 до 2950 мм (опционально до 15 000 мм) |

50 мм |