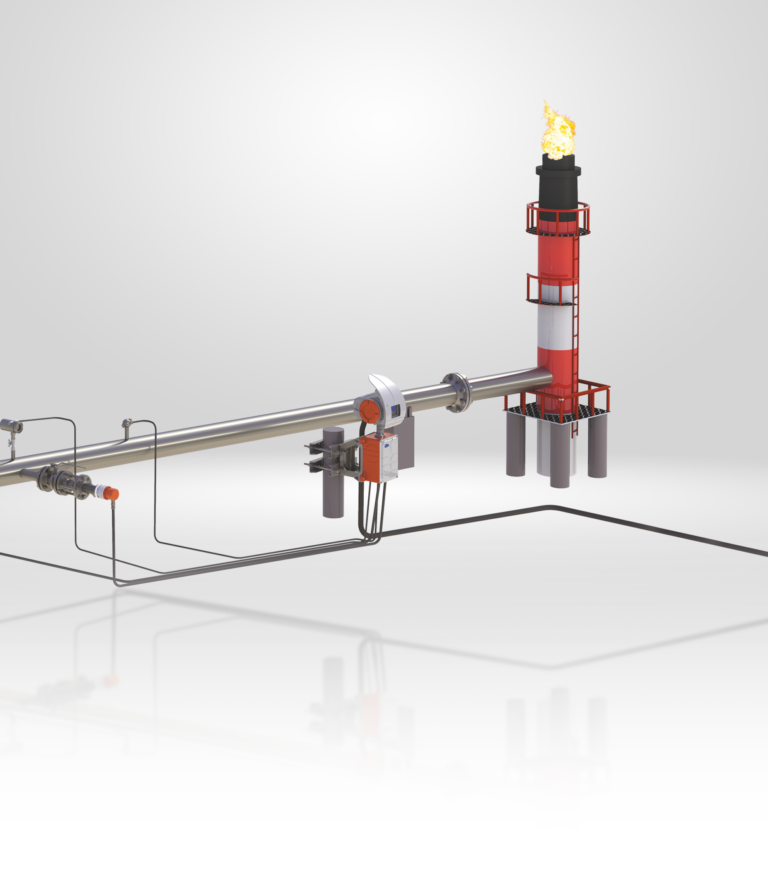

Ultrasonic Flow Meter KTM100 RUS ®

Purpose – Metering of flare gas amount in atmosphere, continuous processes

Benefits:

- Range of gas velocities from 0.03 до 120 m/s according to flare systems safe operation rules of Russian Federal Service for Ecological, Technological and Nuclear Supervision (Rostekhnadzor);

- Metering at high temperatures to +330°C;

- Cutting in and removal of sensors under operating pressure;

- Simulation calibration method;

- Operating pressure to 6.3 МPа – cut-in version;

- Operating pressure to 25 МPа – base version;

- Measurement error of the single-beam version is ±1.5-5%, two-beam version, ±1-3%;

- Installation of the Ex d computing device at the primary sensors installation site;

- Remote indication and control module, length from the installation point – 1000 m;

- Self-check of beams contamination and the flow meter general state;

- Calculation of gas mass flow rate without a density meter by “Hydrocarbon” method;

- Service life – 15 years.

METROLOGY AND TECHNICAL CHARACTERISTICS

| Technical characteristics | КТМ100 RUS | |||

| Type of transmit-receive unit | КТМ100 FL LB | КТМ100 M LB | КТМ100 PR LB | КТМ100 Light |

| Measured flow rate range, m/s |

from 0.03 tо 120 |

from 0.03 tо 90 |

||

| Relative measurement error, % |

1 — beam measurement: 2 or 1.5 2 — beam measurement: 1.5 or 1 |

|||

| Mass flow rate calculation relative error,% |

0,005 |

|||

| Resolution, m/s |

0,001 |

|||

| Gas operating temperature range, °С | from -70 to +1801) | from -40 to +180 | ||

| Recommended angle of installation to the pipe axis,°С | 75 | 90 | 75 | 75 |

| Pipe inner diameter, м¹ | from 0,2 to 1,82) | from 0,05 to 0,63) | ≥0,3 | from 0,05 to 0,6 |

| Operating excess steam pressure, MPa | from -0,05 to 1,64) | from -0,05 to 1,6 | ||

| Ambient temperature, °С |

Transmit-receive units: -70…+60 |

|||

|

IPU: from -50 … +605) |

||||

|

Types of explosion protection |

||||

| Transmit-receive units | 1 Ех d IIC Т6…Т1 Gb | О Ех ia IIC Т6… Т1 Ga | ||

| IPU | 1 Ex db eb ia [ia Ga] T6…T4 IIC Gb X | |||

|

Electric parameters |

||||

| Outputs and interfaces | — frequency (time period signal TPS)/pulse output;

— analog configurable output, current loop with support of HART; — RS-485 with support of Modbus RTU and Modbus ASCII; — Ethernet with support of Modbus TCP; — analog input for temperature and pressure sensors, current loop with support of HART |

|||

| Power voltage, V |

12…30 |

|||

| Input power, W |

Not more than 6 |

|||

| Mean time to failure term, h | 88 000 | |||

| Service life, years | 15 | |||

1) Special designs:

- High temperature design from — 70 °С to + 330 °С

- Low temperature design from — 196 °С to + 100 °С

2) Pipe diameter can be increased, at installation of transmit-receive units along the pipe cross section chord line

3) the range can be increased to 1.2 m by request

4) Optionally to 2.5 МPа, 6.3 МPа or 25 МPа

5) with the use of thermal covers -60+60 °С

- КТМ100 RUS in-process calibration on the operation site

- No diameter and Flow limitations