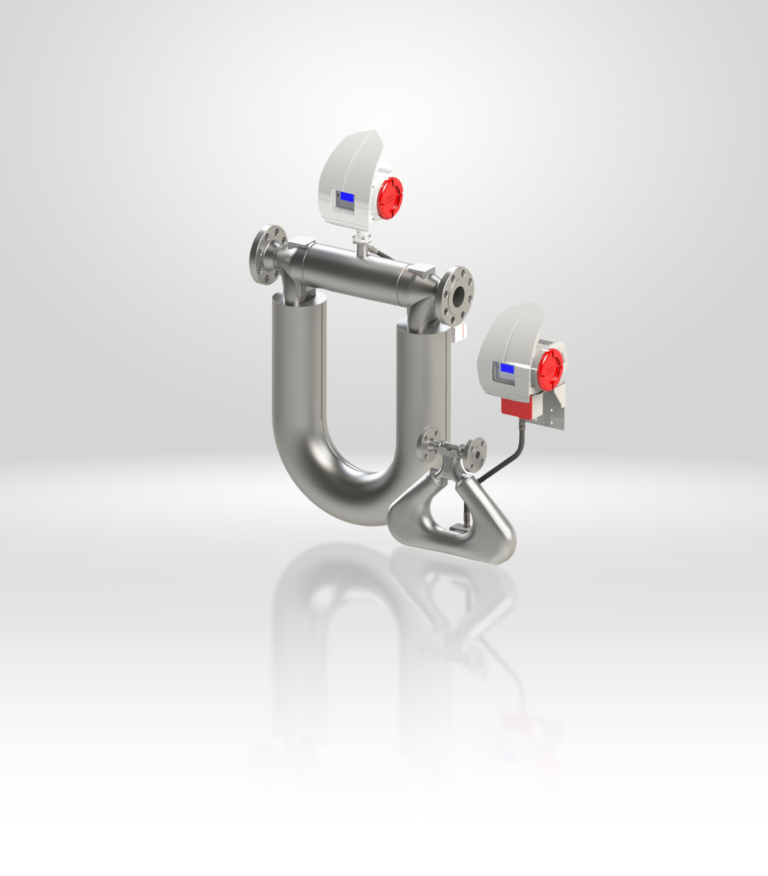

Coriolis Flow Meter KTM RuMASS ®

Commercial and technical metering of oil and oil products, gases, CNG, and cryogenic media

Benefits:

- Significantly higher Qmax Flow rate at the same line DN compared to leading world companies;

- Flow meters with conditional diameters from 8 to 250 mm are made on in-house full cycle production;

- High temperature design to +350°С/+400°С;

- Operating pressure to 40 МPа;

- Reduced hydraulic loss by 15-20% compared to the best world equivalents;

- Crude oil mass and oil products mass measurement function (oil calculator);

- In-built function of correction by pressure and temperature;

- Metrologically provided, certifiable density measurement channel with the error to ±0.2 kg/m³;

- Metrologically provided, certifiable temperature measurement channel;

- Metering of CNG to -196 °С and other cryogenic media;

- Diagnostics of Clever Control Tool Software® * measurement tubes;

- Possibility of the flow meter zero spill calibration either without removal or with removal from the pipeline, and flow meter spill with a compact prover or prover;

- Calibration interval – 5 years, service life – 20 years;

- Possibility of manufacturing with mounting dimensions according to customer’s requirements.

METROLOGY AND TECHNICAL CHARACTERISTICS

| Parameter name | Parameter value | |||||||||||

| Inside diameter, mm | 8 | 15 | 25 | 50 | 80 | 100 | 200 | 250 | ||||

| Mass flow rate, kg/h: | ||||||||||||

|

1300 | 3820 | 18290 | 50580 | 177750 | 566892 | 762000 | 1340000 | ||||

|

2100 | 7500 | 30050 | 91700 | 293400 | 645000 | 1470000 | 2550000 | ||||

| Density measurement range, kg/m3 | from 650 to 2000 | |||||||||||

| Medium temperature, ºС | from -196 to +4002) | |||||||||||

| Médium excess pressure, МПа | to 40 | |||||||||||

| Measurement (calculation) relative error δ0, %: | ||||||||||||

| – mass flow rate and fluid mass 9) | ±0,1; ±0,15 ±0,23); ±0,253); ±0,53) | |||||||||||

| – volume flow rate and fluid volume | ±0,11; ±0,15; ±0,23); ±0,253); ±0,53) | |||||||||||

| – mass flow rate of compressed natural gas and other cryogenic media | ±0,5 | |||||||||||

| – mass flow rate of natural gas and other gas media | ±0,5; ± 0,355) | |||||||||||

| – at simulation calibration method | δ0 + 0,1 | |||||||||||

| – mass and gross mass flow rate of oil/oil products at direct and indirect dynamic measurement method according to GOST 8.587 | ±0,25 | |||||||||||

| – mass and net mass flow rate of oil/oil products at direct and indirect dynamic measurement method according to GOST 8.587 | ±0,35 | |||||||||||

| Repeatability of mass and volume medium flow rate, % | ±0,05 | |||||||||||

| Dynamic measurement range (from nominal flow rate) | 1:208) | |||||||||||

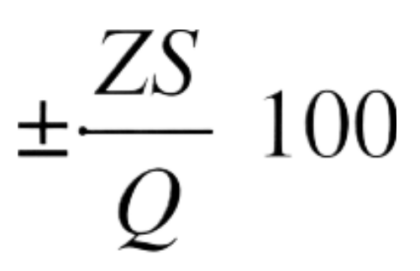

| Zero stability ZS 8), kg/h | 0,065 | 0,16 | 0,65 | 2 | 6,8 | 28 | 38 | 67 | ||||

| Density measurement error, kg/m3 | ±104); ±5; ±1; ±0,5; ±0,37); ±0,26) | |||||||||||

| Density measurement repeatability, kg/m3 | ±0,1 | |||||||||||

| Temperature measurement repeatability, ºС | ±1 | |||||||||||

| Temperature repeatability, ºС | ±0,2 | |||||||||||

| Calibration Interval, years | 5 | |||||||||||

| Ambient temperature, °С | from- 50 to + 60 | |||||||||||

| IP degree of protection according to GOST 14254 (IEC 60529) | IP66/IP67 – measurement housing and standard version IPU;

IP66/IP68 – Light version IPU |

|||||||||||

| IPU explosion-proof marking: | ||||||||||||

| – standard version IPU | 1Ex db eb [ia Ga] IIB T6 Gb X

1Ex db eb [ia Ga] IIC T6 Gb X |

|||||||||||

| – Light version IPU | 1Ex db e [ia Ga] IIB T6 Gb X

1Ex db e [ia Ga] IIC T6 Gb X |

|||||||||||

| Measurement housing explosion-proof marking | 0Ex ia IIB T6…T1 Ga X

0Ex ia IIC T6…T1 Ga X |

|||||||||||

| Outputs and interfaces: | ||||||||||||

| – frequency (time period signal TPS)/pulse output;

– analog configurable output, current loop with support of HART; – RS-485 with support of Modbus RTU and Modbus ASCII; – Ethernet with support of Modbus TCP; – analog input for temperature and pressure sensors, current loop with support of HART |

||||||||||||

| Direct current supply voltage 10), V | from 12 to 30 | |||||||||||

| Input power, W | 15 | |||||||||||

| Mean time to failure term, h | 150 000 | |||||||||||

| Service life, years | 20 | |||||||||||

| Remarks:

1) Nominal flow rate Qnom is the flow rate at which the value of pressure drop on the metering device with the use of water at the temperature from 20 °С tо 25 °С and pressure from 0.1 tо 0.2 MPa as medium is approximately 0.1 MPa; 2) With the function of flow rate and density readings compensation by temperature; 3) At check and/or calibration with a compact prover, prover, 2nd rank working standards; 4) At simulation calibration; 5) At calibration on gas with the use of calibration factors; 6) At calibration in laboratory with the operation site conditions; 7) At calibration in operating conditions at the operation site with a flow density meter, working standard; 8) At the mass flow rate of Q < 0,05·Qnom, the relative measurement error is calculated by the formula 9) At calibration of flow meters as part of CQCS (crude quality control system), OPQCS (oil product quality control system) or LAS (loading automated system), their further operation is permitted with the limit permissible relative measurement error of fluid mass flow rate (mass) ±0.25% as working and ±0.2% as control; 10) 220В, 50 Hz with the use of voltage converter. |

||||||||||||

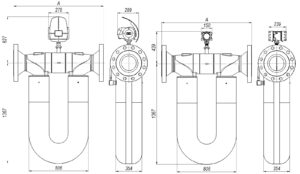

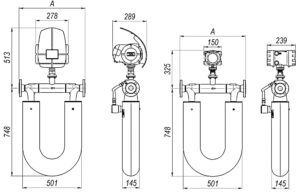

FLOW METER OVERALL AND CONNECTION DIMENSIONS

| а) | б) |

KTM RuMASS 250 Flow Meter:

а) with the standard design IPU; b) with the Light design IPU

Flanges on KTM RuMASS 250 of standard and cryogenic design

| Code | DN | PN | Standard | Flange type | Sealing surface type | A size, mm | Weight (with stand. IPU), kg |

Weight (with Light IPU), kg |

Weight (without IPU), kg |

| 801 | DN200 | – | DIN 32676 | Hygienic fitting | – | 964 | 336 | 327 | 314 |

| 821 | DN200 | PN40 | GOST 33259 | 11 (butt weld) | B (joggle) | 1084 | 383 | 374 | 361 |

| 822 | DN200 | PN40 | GOST 33259 | 11 (butt weld) | D (groove) | 1084 | 383 | 374 | 361 |

| 823 | DN200 | PN40 | EN 1092-1 | Weld neck flange | Type B1 | 1084 | 376 | 367 | 354 |

| 824 | NPS8 | CL150 | ASME B 16.5 | Weld neck flange | Raised face | 1111 | 375 | 366 | 353 |

| 831 | NPS8 | CL300 | ASME B 16.5 | Weld neck flange | Raised face | 1131 | 400 | 391 | 378 |

| 841 | DN200 | PN100 | GOST 33259 | 11 (butt weld) | B (joggle) | 1168 | 443 | 434 | 421 |

| 842 | DN200 | PN100 | GOST 33259 | 11 (butt weld) | D (groove) | 1168 | 443 | 434 | 421 |

| 843 | DN200 | PN100 | EN 1092-1 | Weld neck flange | Type B2 | 1168 | 435 | 426 | 413 |

| 844 | NPS8 | CL600 | ASME B 16.5 | Weld neck flange | Raised face | 1175 | 444 | 435 | 422 |

| 921 | DN250 | PN40 | GOST 33259 | 11 (butt weld) | B (joggle) | 1118 | 409 | 400 | 387 |

| 922 | DN250 | PN40 | GOST 33259 | 11 (butt weld) | D (groove) | 1118 | 409 | 400 | 387 |

| 923 | DN250 | PN40 | EN 1092-1 | Weld neck flange | Type B1 | 1118 | 403 | 394 | 381 |

| 924 | NPS10 | CL150 | ASME B 16.5 | Weld neck flange | Raised face | 1111 | 390 | 381 | 368 |

| 931 | NPS10 | CL300 | ASME B 16.5 | Weld neck flange | Raised face | 1143 | 429 | 420 | 407 |

| 941 | DN250 | PN100 | GOST 33259 | 11 (butt weld) | B (joggle) | 1222 | 505 | 496 | 483 |

| 942 | DN250 | PN100 | GOST 33259 | 11 (butt weld) | D (groove) | 1222 | 505 | 496 | 483 |

| 943 | DN250 | PN100 | EN 1092-1 | Weld neck flange | Type B2 | 1222 | 497 | 488 | 475 |

| 944 | NPS10 | CL600 | ASME B 16.5 | Weld neck flange | Raised face | 1213 | 516 | 507 | 494 |

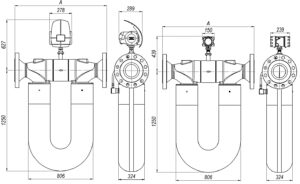

| а) | б) |

KTM RuMASS 200 Flow Meter:

а) with the standard design IPU; b) with the Light design IPU

Flanges on KTM RuMASS 200 of standard and cryogenic design

| Code | DN | PN | Standard | Flange type | Sealing surface type | A size, mm | Weight (with stand. IPU), kg |

Weight (with Light IPU), kg |

(without IPU), kg |

| 701 | DN150 | – | DIN 32676 | Hygienic fitting | – | 938 | 303 | 295 | 281 |

| 721 | DN150 | PN40 | GOST 33259 | 11 (butt weld) | B (joggle) | 1032 | 328 | 320 | 306 |

| 722 | DN150 | PN40 | GOST 33259 | 11 (butt weld) | D (groove) | 1032 | 328 | 320 | 306 |

| 723 | DN150 | PN40 | EN 1092-1 | Weld neck flange | Type B1 | 1032 | 325 | 316 | 303 |

| 724 | NPS6 | CL150 | ASME B 16.5 | Weld neck flange | Raised face | 1060 | 326 | 317 | 304 |

| 731 | NPS6 | CL300 | ASME B 16.5 | Weld neck flange | Raised face | 1079 | 344 | 335 | 322 |

| 741 | DN150 | PN100 | GOST 33259 | 11 (butt weld) | B (joggle) | 1112 | 368 | 359 | 346 |

| 742 | DN150 | PN100 | GOST 33259 | 11 (butt weld) | D (groove) | 1112 | 368 | 359 | 346 |

| 743 | DN150 | PN100 | EN 1092-1 | Weld neck flange | Type B2 | 1112 | 359 | 349 | 337 |

| 744 | NPS6 | CL600 | ASME B 16.5 | Weld neck flange | Raised face | 1117 | 373 | 391 | 351 |

| 801 | DN200 | – | DIN 32676 | Hygienic fitting | – | 938 | 304 | 295 | 282 |

| 821 | DN200 | PN40 | GOST 33259 | 11 (butt weld) | B (joggle) | 1058 | 351 | 342 | 329 |

| 822 | DN200 | PN40 | GOST 33259 | 11 (butt weld) | D (groove) | 1058 | 351 | 342 | 329 |

| 823 | DN200 | PN40 | EN 1092-1 | Weld neck flange | Type B1 | 1058 | 344 | 335 | 322 |

| 824 | NPS8 | CL150 | ASME B 16.5 | Weld neck flange | Raised face | 1085 | 342 | 333 | 320 |

| 831 | NPS8 | CL300 | ASME B 16.5 | Weld neck flange | Raised face | 1105 | 368 | 359 | 346 |

| 841 | DN200 | PN100 | GOST 33259 | 11 (butt weld) | B (joggle) | 1142 | 410 | 402 | 388 |

| 842 | DN200 | PN100 | GOST 33259 | 11 (butt weld) | D (groove) | 1142 | 410 | 402 | 388 |

| 843 | DN200 | PN100 | EN 1092-1 | Weld neck flange | Type B2 | 1142 | 402 | 393 | 380 |

| 844 | NPS8 | CL600 | ASME B 16.5 | Weld neck flange | Raised face | 1149 | 412 | 403 | 390 |

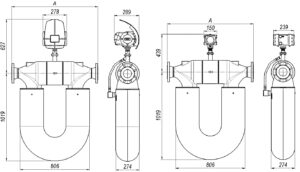

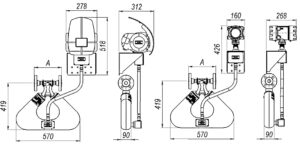

| а) | б) |

KTM RuMASS 100 Flow Meter:

а) with the standard design IPU; b) with the Light design IPU

Flanges on KTM RuMASS 100 of standard and cryogenic design

| Code | DN | PN | Standart | Flange type | Sealing surface type | A size, mm | Weight (with stand. IPU), kg |

Weight (with Light IPU), kg |

(without IPU), kg |

| 601 | 100mm | 10K | JIS B 2220 | Weld neck flange | Raised face | 999 | 239 | 230 | 217 |

| 611 | 100mm | 20K | JIS B 2220 | Weld neck flange | Raised face | 1011 | 243 | 234 | 221 |

| 621 | DN100 | PN40 | GOST 33259 | 11 (butt weld) | B (joggle) | 999 | 245 | 237 | 223 |

| 622 | DN100 | PN40 | GOST 33259 | 11 (butt weld) | D (groove) | 999 | 245 | 236 | 223 |

| 623 | DN100 | PN40 | EN 1092-1 | Weld neck flange | Type B1 | 999 | 243 | 235 | 221 |

| 624 | DN100 | PN40 | EN 1092-1 | Weld neck flange | Type D | 999 | 243 | 234 | 221 |

| 625 | NPS4 | CL150 | ASME B 16.5 | Weld neck flange | Raised face | 1021 | 245 | 237 | 223 |

| 631 | NPS4 | CL300 | ASME B 16.5 | Weld neck flange | Raised face | 1041 | 255 | 246 | 233 |

| 641 | DN100 | PN100 | GOST 33259 | 11 (butt weld) | B (joggle) | 1049 | 259 | 250 | 237 |

| 642 | DN100 | PN100 | GOST 33259 | 11 (butt weld) | D (groove) | 1049 | 258 | 250 | 236 |

| 643 | DN100 | PN100 | EN 1092-1 | Weld neck flange | Type B1 | 1049 | 257 | 248 | 235 |

| 644 | DN100 | PN100 | EN 1092-1 | Weld neck flange | Type D | 1049 | 256 | 248 | 234 |

| 645 | NPS4 | CL600 | ASME B 16.5 | Weld neck flange | Raised face | 1084 | 261 | 256 | 239 |

| 701 | 150mm | 10K | JIS B 2220 | Weld neck flange | Raised face | 999 | 252 | 240 | 230 |

| 721 | DN150 | PN40 | GOST 33259 | 11 (butt weld) | B (joggle) | 1018 | 258 | 250 | 236 |

| 722 | DN150 | PN40 | GOST 33259 | 11 (butt weld) | D (groove) | 1018 | 258 | 249 | 236 |

| 723 | DN150 | PN40 | EN 1092-1 | Weld neck flange | Type B1 | 1018 | 256 | 247 | 234 |

| 724 | DN150 | PN40 | EN 1092-1 | Weld neck flange | Type D | 1018 | 255 | 247 | 233 |

| 725 | NPS6 | CL150 | ASME B 16.5 | Weld neck flange | Raised face | 1024 | 253 | 245 | 231 |

| 731 | NPS6 | CL300 | ASME B 16.5 | Weld neck flange | Raised face | 1049 | 272 | 263 | 250 |

| 741 | DN150 | PN100 | GOST 33259 | 11 (butt weld) | B (joggle) | 1099 | 293 | 284 | 271 |

| 742 | DN150 | PN100 | GOST 33259 | 11 (butt weld) | D (groove) | 1099 | 292 | 284 | 270 |

| 743 | DN150 | PN100 | EN 1092-1 | Weld neck flange | Type B1 | 1099 | 289 | 280 | 267 |

| 744 | DN150 | PN100 | EN 1092-1 | Weld neck flange | Type D | 1099 | 288 | 280 | 266 |

| 754 | NPS6 | CL600 | ASME B 16.5 | Weld neck flange | Raised face | 1105 | 281 | 273 | 259 |

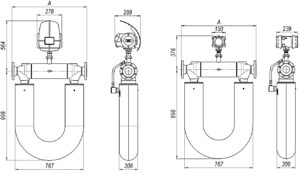

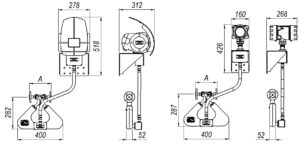

| а) | б) |

KTM RuMASS 80 Flow Meter:

а) with the standard design IPU; b) with the Light design IPU

Flanges on KTM RuMASS 80 of standard and cryogenic design

| Code | DN | PN | Standart | Flange type | Sealing surface type | A size, mm | Weight (with stand. IPU), kg |

Weight (with Light IPU), kg |

(without IPU), kg |

| 501 | DN80 | – | DIN 32676 | Hygienic fitting | – | 813 | 130 | 108 | |

| 502 | 80mm | 10K | JIS B 2220 | Weld neck flange | Raised face | 848 | 136 | 114 | |

| 511 | 80mm | 20K | JIS B 2220 | Weld neck flange | Raised face | 848 | 138 | 116 | |

| 521 | DN80 | PN40 | GOST 33259 | 11 (butt weld) | B (joggle) | 840 | 139 | 117 | |

| 522 | DN80 | PN40 | GOST 33259 | 11 (butt weld) | D (groove) | 840 | 139 | 117 | |

| 523 | DN80 | PN40 | EN 1092-1 | Weld neck flange | Type B1 | 832 | 139 | 117 | |

| 524 | DN80 | PN40 | EN 1092-1 | Weld neck flange | Type D | 832 | 139 | 117 | |

| 525 | NPS3 | CL150 | ASME B 16.5 | Weld neck flange | Raised face | 856 | 140 | 118 | |

| 531 | NPS3 | CL300 | ASME B 16.5 | Weld neck flange | Raised face | 875 | 144 | 122 | |

| 541 | DN80 | PN100 | GOST 33259 | 11 (butt weld) | B (joggle) | 904 | 149 | 127 | |

| 542 | DN80 | PN100 | GOST 33259 | 11 (butt weld) | D (groove) | 904 | 149 | 127 | |

| 543 | DN80 | PN100 | EN 1092-1 | Weld neck flange | Type B1 | 872 | 147 | 125 | |

| 544 | DN80 | PN100 | EN 1092-1 | Weld neck flange | Type D | 872 | 147 | 125 | |

| 545 | NPS3 | CL600 | ASME B 16.5 | Weld neck flange | Raised face | 894 | 145 | 123 | |

| 621 | DN100 | PN40 | GOST 33259 | 11 (butt weld) | B (joggle) | 860 | 144 | 122 | |

| 622 | DN100 | PN40 | GOST 33259 | 11 (butt weld) | D (groove) | 860 | 144 | 122 | |

| 623 | DN100 | PN40 | EN 1092-1 | Weld neck flange | Type B1 | 845 | 143 | 121 | |

| 624 | DN100 | PN40 | EN 1092-1 | Weld neck flange | Type D | 845 | 143 | 121 | |

| 625 | NPS4 | CL150 | ASME B 16.5 | Weld neck flange | Raised face | 865 | 144 | 122 | |

| 631 | NPS4 | CL300 | ASME B 16.5 | Weld neck flange | Raised face | 889 | 154 | 132 | |

| 641 | DN100 | PN100 | GOST 33259 | 11 (butt weld) | B (joggle) | 924 | 159 | 137 | |

| 642 | DN100 | PN100 | GOST 33259 | 11 (butt weld) | D (groove) | 924 | 159 | 137 | |

| 643 | DN100 | PN100 | EN 1092-1 | Weld neck flange | Type B1 | 896 | 156 | 134 | |

| 644 | DN100 | PN100 | EN 1092-1 | Weld neck flange | Type D | 896 | 156 | 134 | |

| 645 | NPS4 | CL600 | ASME B 16.5 | Weld neck flange | Raised face | 932 | 155 | 133 |

| а) | б) |

KTM RuMASS 50 Flow Meter:

а) with the standard design IPU; b) with the Light design IPU

Flanges on KTM RuMASS 50 of standard and cryogenic design

| Code | DN | PN | Standart | Flange type | Sealing surface type | A size, mm | Weight (with stand. IPU), kg |

Weight (with Light IPU), kg |

(without IPU), kg | ||||||||||

| 301 | DN40 | – | DIN 32676 | Hygienic fitting | – | 543 | 54 | 46 | 32 | ||||||||||

| 302 | 40mm | 10K | JIS B 2220 | Weld neck flange | Raised face | 548 | 58 | 49 | 36 | ||||||||||

| 311 | 40mm | 20K | JIS B 2220 | Weld neck flange | Raised face | 548 | 58 | 50 | 36 | ||||||||||

| 321 | DN40 | PN40 | GOST 33259 | 11 (butt weld) | B (joggle) | 561 | 59 | 50 | 37 | ||||||||||

| 322 | DN40 | PN40 | GOST 33259 | 11 (butt weld) | D (groove) | 561 | 58 | 50 | 36 | ||||||||||

| 323 | DN40 | PN40 | EN 1092-1 | Weld neck flange | Type B1 | 547 | 58 | 50 | 36 | ||||||||||

| 324 | DN40 | PN40 | EN 1092-1 | Weld neck flange | Type D | 547 | 58 | 50 | 36 | ||||||||||

| 325 | NPS1½ | CL150 | ASME B 16.5 | Weld neck flange | Raised face | 581 | 58 | 50 | 36 | ||||||||||

| 331 | NPS1½ | CL300 | ASME B 16.5 | Weld neck flange | Raised face | 594 | 60 | 52 | 38 | ||||||||||

| 341 | DN40 | PN100 | GOST 33259 | 11 (butt weld) | B (joggle) | 605 | 62 | 54 | 40 | ||||||||||

| 342 | DN40 | PN100 | GOST 33259 | 11 (butt weld) | D (groove) | 605 | 62 | 54 | 40 | ||||||||||

| 343 | DN40 | PN100 | EN 1092-1 | Weld neck flange | Type B1 | 580 | 62 | 54 | 40 | ||||||||||

| 344 | DN40 | PN100 | EN 1092-1 | Weld neck flange | Type D | 580 | 62 | 54 | 40 | ||||||||||

| 345 | NPS1½ | CL600 | ASME B 16.5 | Weld neck flange | Raised face | 605 | 61 | 53 | 39 | ||||||||||

| 401 | DN50 | – | DIN 32676 | Hygienic fitting | – | 543 | 54 | 46 | 32 | ||||||||||

| 421 | DN50 | PN40 | GOST 33259 | 11 (butt weld) | B (joggle) | 561 | 60 | 52 | 38 | ||||||||||

| 422 | DN50 | PN40 | GOST 33259 | 11 (butt weld) | D (groove) | 561 | 60 | 52 | 38 | ||||||||||

| 423 | DN50 | PN40 | EN 1092-1 | Weld neck flange | Type B1 | 553 | 60 | 52 | 38 | ||||||||||

| 424 | DN50 | PN40 | EN 1092-1 | Weld neck flange | Type D | 553 | 60 | 52 | 38 | ||||||||||

| 425 | NPS2 | CL150 | ASME B 16.5 | Weld neck flange | Raised face | 581 | 59 | 51 | 37 | ||||||||||

| 431 | NPS2 | CL300 | ASME B 16.5 | Weld neck flange | Raised face | 594 | 62 | 54 | 40 | ||||||||||

| 441 | DN50 | PN100 | GOST 33259 | 11 (butt weld) | B (joggle) | 607 | 66 | 58 | 44 | ||||||||||

| 442 | DN50 | PN100 | GOST 33259 | 11 (butt weld) | D (groove) | 607 | 66 | 58 | 44 | ||||||||||

| 443 | DN50 | PN100 | EN 1092-1 | Weld neck flange | Type B1 | 580 | 65 | 57 | 43 | ||||||||||

| 444 | DN50 | PN100 | EN 1092-1 | Weld neck flange | Type D | 580 | 65 | 57 | 43 | ||||||||||

| 445 | NPS2 | CL600 | ASME B 16.5 | Weld neck flange | Raised face | 600 | 63 | 55 | 41 | ||||||||||

| а) | б) |

KTM RuMASS 25 Flow Meter:

а) with the standard design IPU; b) with the Light design IPU

Flanges on KTM RuMASS 25 of standard and cryogenic design

| Code | DN | PN | Standart | Flange type | Sealing surface type | A size, mm | Weight (with stand. IPU), kg |

Weight (with Light IPU), kg |

(without IPU), kg |

| 201 | DN25 | – | DIN 32676 | Hygienic fitting | – | 213 | 43 | 35 | 17 |

| 202 | 25mm | 10K | JIS B 2220 | Weld neck flange | Raised face | 211 | 46 | 37 | 20 |

| 211 | 25mm | 20K | JIS B 2220 | Weld neck flange | Raised face | 211 | 46 | 38 | 20 |

| 221 | DN25 | PN40 | GOST 33259 | 11 (butt weld) | B (joggle) | 204 | 46 | 37 | 20 |

| 222 | DN25 | PN40 | GOST 33259 | 11 (butt weld) | D (groove) | 204 | 46 | 37 | 20 |

| 223 | DN25 | PN40 | EN 1092-1 | Weld neck flange | Type B1 | 211 | 46 | 37 | 20 |

| 224 | DN25 | PN40 | EN 1092-1 | Weld neck flange | Type D | 211 | 46 | 37 | 20 |

| 225 | NPS1 | CL150 | ASME B 16.5 | Weld neck flange | Raised face | 236 | 45 | 37 | 19 |

| 231 | NPS1 | CL300 | ASME B 16.5 | Weld neck flange | Raised face | 248 | 47 | 38 | 21 |

| 241 | DN25 | PN100 | GOST 33259 | 11 (butt weld) | B (joggle) | 244 | 48 | 40 | 22 |

| 242 | DN25 | PN100 | GOST 33259 | 11 (butt weld) | D (groove) | 244 | 48 | 40 | 22 |

| 243 | DN25 | PN100 | EN 1092-1 | Weld neck flange | Type B1 | 244 | 49 | 40 | 23 |

| 244 | DN25 | PN100 | EN 1092-1 | Weld neck flange | Type D | 244 | 49 | 40 | 23 |

| 245 | NPS1 | CL600 | ASME B 16.5 | Weld neck flange | Raised face | 260 | 47 | 39 | 21 |

| 341 | NPS1½ | CL600 | ASME B 16.5 | Weld neck flange | Raised face | 260 | 49 | 41 | 23 |

| а) | б) |

KTM RuMASS 15 Flow Meter:

а) with the standard design IPU; b) with the Light design IPU

Flanges on KTM RuMASS 15 of standard and cryogenic design

| Code | DN | PN | Standart | Flange type | Sealing surface type | A size, mm | Weight (with stand. IPU), kg |

Weight (with Light IPU), kg |

(without IPU), kg |

| 101 | DN15 | – | DIN 32676 | Hygienic fitting | – | 151 | 33 | 24 | 7 |

| 102 | 15mm | 10K | JIS B 2220 | Weld neck flange | Raised face | 177 | 34 | 26 | 8 |

| 111 | 15mm | 20K | JIS B 2220 | Weld neck flange | Raised face | 183 | 34 | 26 | 8 |

| 121 | DN15 | PN40 | GOST 33259 | 11 (butt weld) | B (joggle) | 191 | 34 | 26 | 8 |

| 122 | DN15 | PN40 | GOST 33259 | 11 (butt weld) | D (groove) | 191 | 34 | 26 | 8 |

| 123 | DN15 | PN40 | EN 1092-1 | Weld neck flange | Type B1 | 191 | 35 | 26 | 9 |

| 124 | DN15 | PN40 | EN 1092-1 | Weld neck flange | Type D | 191 | 35 | 26 | 9 |

| 125 | NPS½ | CL150 | ASME B 16.5 | Weld neck flange | Raised face | 211 | 34 | 25 | 8 |

| 131 | NPS½ | CL300 | ASME B 16.5 | Weld neck flange | Raised face | 221 | 34 | 26 | 8 |

| 141 | DN15 | PN100 | GOST 33259 | 11 (butt weld) | B (joggle) | 205 | 35 | 27 | 9 |

| 142 | DN15 | PN100 | GOST 33259 | 11 (butt weld) | D (groove) | 205 | 35 | 27 | 9 |

| 143 | DN15 | PN100 | EN 1092-1 | Weld neck flange | Type B1 | 205 | 35 | 27 | 9 |

| 144 | DN15 | PN100 | EN 1092-1 | Weld neck flange | Type D | 205 | 35 | 27 | 9 |

| 145 | NPS½ | CL600 | ASME B 16.5 | Weld neck flange | Raised face | 233 | 35 | 26 | 9 |

| 221 | DN25 | PN40 | EN 1092-1 | Weld neck flange | Type B1 | 195 | 35 | 27 | 9 |

| 222 | DN25 | PN40 | EN 1092-1 | Weld neck flange | Type D | 195 | 35 | 27 | 9 |

;

;