Coriolis Flow Meter KTM RuMASS E — series®

Commercial and technical metering of oil and oil products, gases, CNG, and cryogenic media

Advantages:

- Significantly greater flow rate Qmax with the same nominal line diameter compared with leading

world companies. - Flowmeters with nominal diameters from 2 to 300 mm are manufactured at an in-house

full-cycle production facility. - High-temperature design up to +350°С/+400°С.

- Working pressure up to 40 MPa.

- Reduced hydraulic losses by 15–20% compared with the best foreign

counterparts. - Function for calculating the mass of oil and petroleum products (oil calculator).

- Built-in function for pressure and temperature correction.

- Metrologically supported, verifiable density measurement channel with an error

up to ±0.2 kg/m³. - Metrologically supported, verifiable temperature measurement channel.

- Accounting of LNG down to -196 °С and other cryogenic media.

- Diagnostic function for the condition of measuring tubes Clever Control Tool Software® *.

- Possibility of dry verification of the flowmeter without removal or with removal from the

pipeline, as well as flowmeter proving using a compact prover or a

pipe-prover installation (PPI). - Calibration interval – 5 years, service life – 20 years.

- Possibility of manufacturing with installation dimensions according to customer requirements.

METROLOGICAL AND TECHNICAL CHARACTERISTICS

| Parameter name | Parameter value | |||||||||

| 2 | 8 | 15 | 25 | 50 | 80 | 100 | 200 | 250 | ||

| Mass flow, kg/h: | Nominal1) | 120 | 1000 | 3820 | 18290 | 50580 | 177750 | 566892 | 762000 | 1340000 |

| Максимальный | 130 | 1800 | 7500 | 30050 | 91700 | 293400 | 645000 | 1470000 | 2550000 | |

| Zero stability ZS8), kg/h | 0,006 | 0,05 | 0,19 | 0,92 | 2,53 | 8,9 | 28 | 38 | 67 | |

| Density measurement range, kg/m3 | от 650 до 2000 | |||||||||

| Dynamic range of measurements (from nominal flow) | 1:208) | |||||||||

| Limits of relative error of measurements (calculations) δ0, %: | ||||||||||

| mass flow and liquid mass9) | ±0,1; | ±0,15; | ±0,23; | ±0,253); | ±0,53 | |||||

| volume flow and liquid volume | ±0,11; ±0,15; ±0,23); ±0,253); ±0,53) | |||||||||

| mass flow of liquefied natural gas and other cryogenic media | ±0,5 | |||||||||

| mass flow of natural gas and other gaseous media | ±0,5; ± 0,355) | |||||||||

| with the simulation verification method | δ0 + 0,1 | |||||||||

| mass and gross mass flow rate of oil/petroleum products using direct and indirect methods of dynamic measurements according to GOST 8.587 | ±0,25 | |||||||||

| mass and net mass flow of oil/petroleum products using direct and indirect methods of dynamic measurements according to GOST 8.587 | ±0,35 | |||||||||

| Repeatability of mass and volume flow of working medium, % | ±0,05 | |||||||||

| Density measurement error, kg/m3 | ±104); ±5; ±1; ±0,5; ±0,37); ±0,26) | |||||||||

| Repeatability of density measurement, kg/m3 | ±0,1 | |||||||||

| Temperature measurement error, ºС | ±1 | |||||||||

| Temperature repeatability, ºС | ±0,2 | |||||||||

| Working environment temperature, ºС | standard integral version | from minus 60 to plus 1252) | ||||||||

| standard remote version | from minus 60 to plus 2002) | |||||||||

| cryogenic version (spaced) | from minus 196 to plus 802) | |||||||||

| high temperature version (remote) | from minus 10 to plus 4002) | |||||||||

| 1) Nominal flow rate Qnom – flow rate at which the pressure drop across the measuring device, when using water as a medium with a temperature of 20 °C to 25 °C and a pressure of 0.1 to 0.2 MPa, is approximately 0.1 MPa;

2) With the function of compensating flow and density readings by temperature; 3) When calibrating and/or checking using a compact prover, a pipe piston unit, 2nd category standards; 4) During simulation verification; 5) When calibrating on gas using calibration coefficients; 6) When calibrated in a laboratory under the conditions of the operating site; 7) When calibrated under operating conditions on site using an in-line density meter, a working standard; 8) For mass flow Q < 0.05·Qnom, the relative measurement error is calculated by the formula; 9) When calibrating flow meters as part of SIKN, SIKNP or ASN, their further operation is allowed with a limit of permissible relative error in measuring liquid mass flow (mass) of ±0.25% as a working one and ±0.2% as a control one. |

||||||||||

|

|

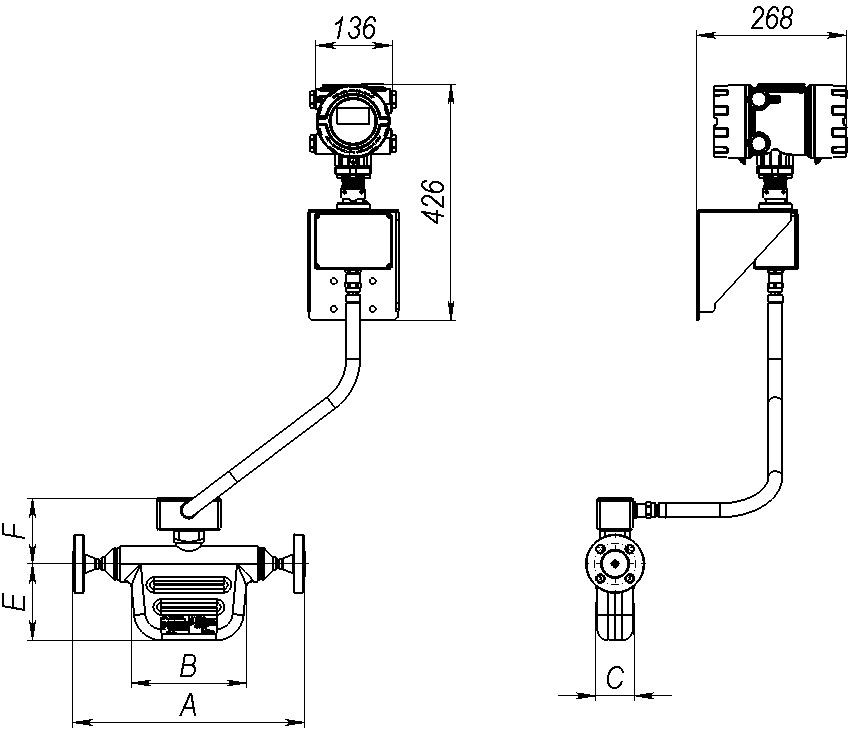

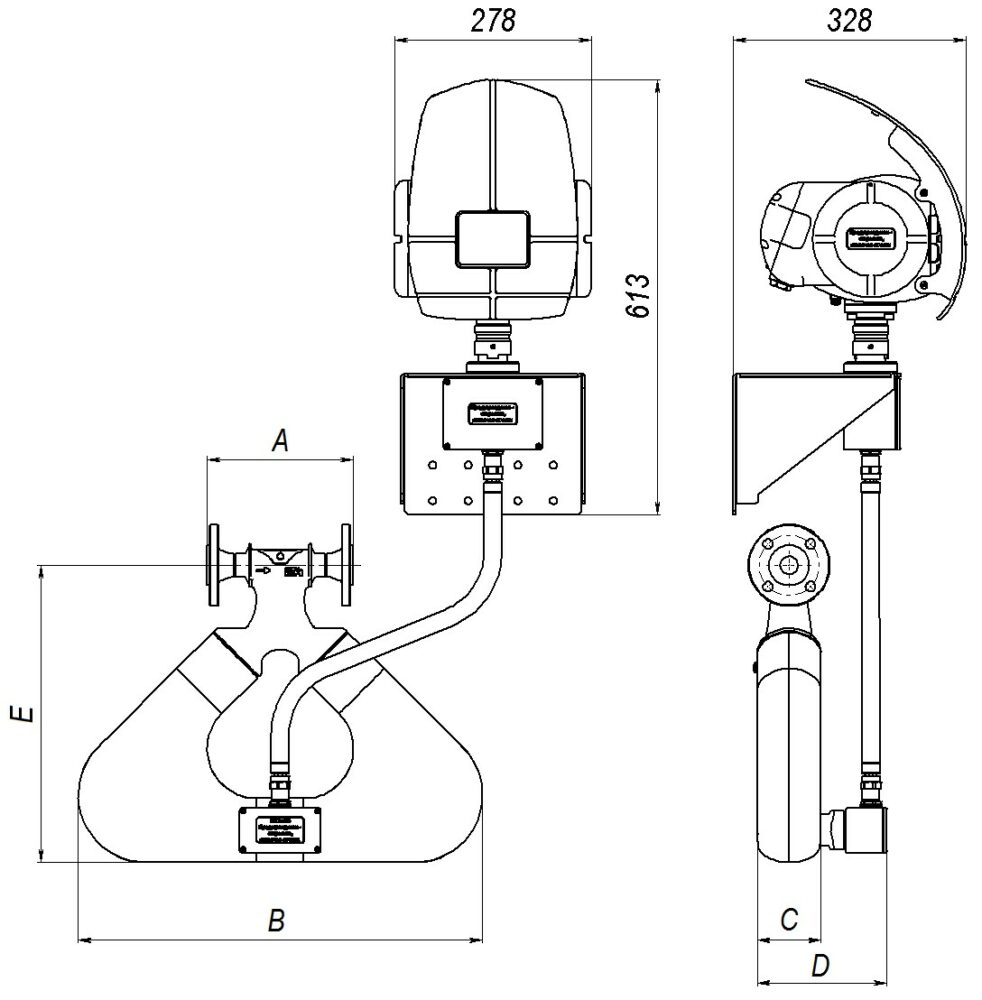

| a)KTM RuMASS E 002-008 with BOI Lite |

b)KTM RuMASS E 002-008 with standard BOI |

|

Overall dimensions of the Coriolis flow meter |

|||||

|

Sizes |

Dimension A, mm |

Dimension B, mm |

Dimension C, mm |

Dimension E, mm |

Dimension F, mm |

|

KTM RuMASS E 002 |

304-412 * |

148 |

50 |

113 |

122 |

|

KTM RuMASS E 008 |

392-500 * |

206 |

70 |

138 |

119 |

|

_______________ * Depending on flange design |

|||||

|

|

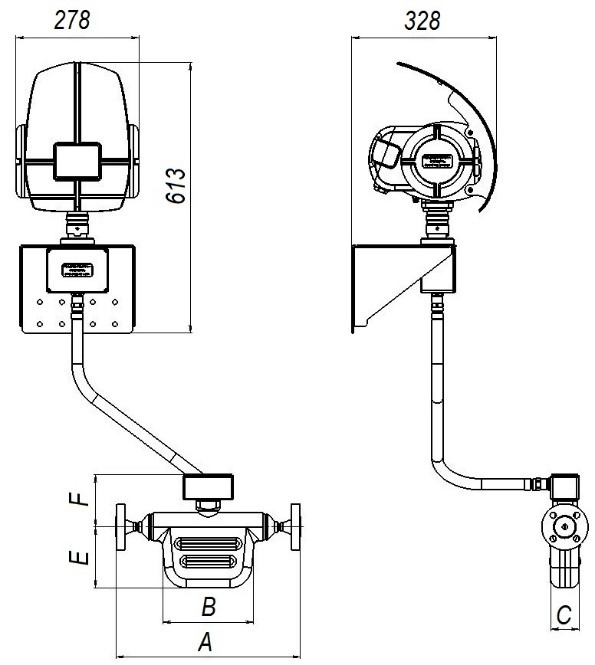

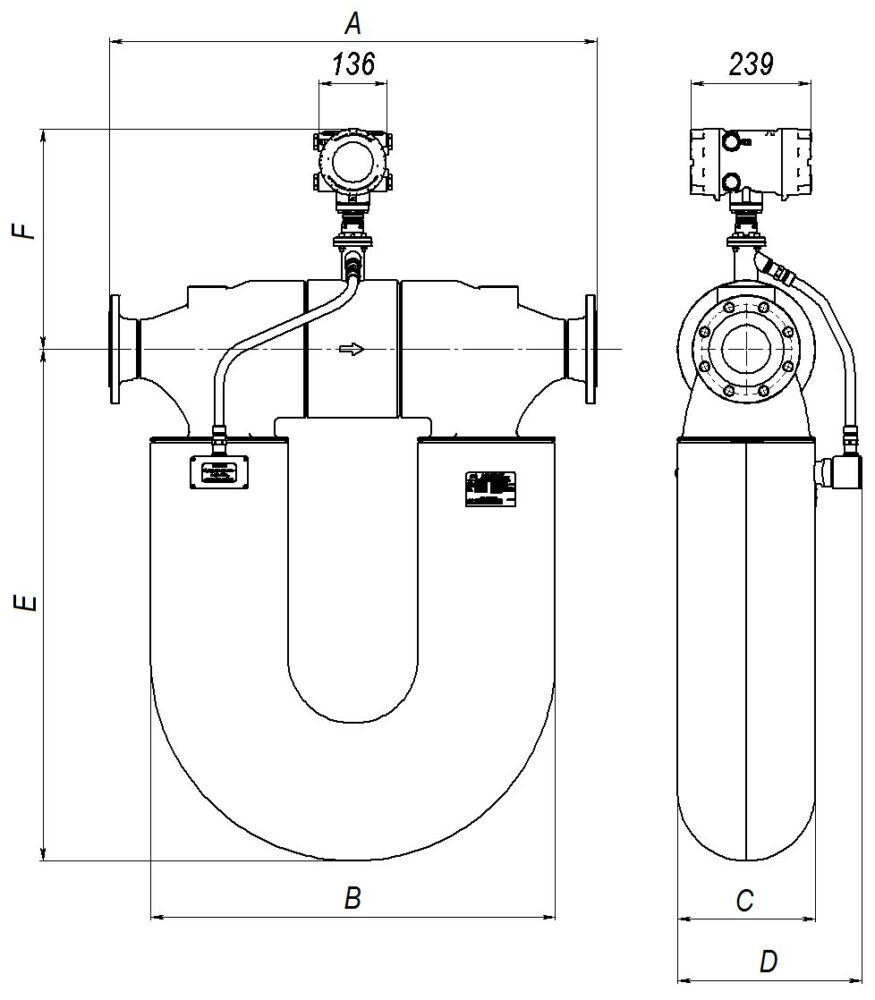

| a) KTM RuMASS E 015-025 with BOI Lite |

b) KTM RuMASS E 015-025 with standard BOI |

|

Overall dimensions of the Coriolis flow meter |

|||||

|

Sizes |

Dimension A, mm |

Dimension B, mm |

Dimension C, mm |

Dimension D, mm |

Dimension E, mm |

|

KTM RuMASS E 015 |

151-306 * |

400 |

56 |

153 |

282 |

|

KTM RuMASS E 025 |

204-348 * |

570 |

90 |

183 |

419 |

|

_______________ * Depending on flange design |

|||||

|

|

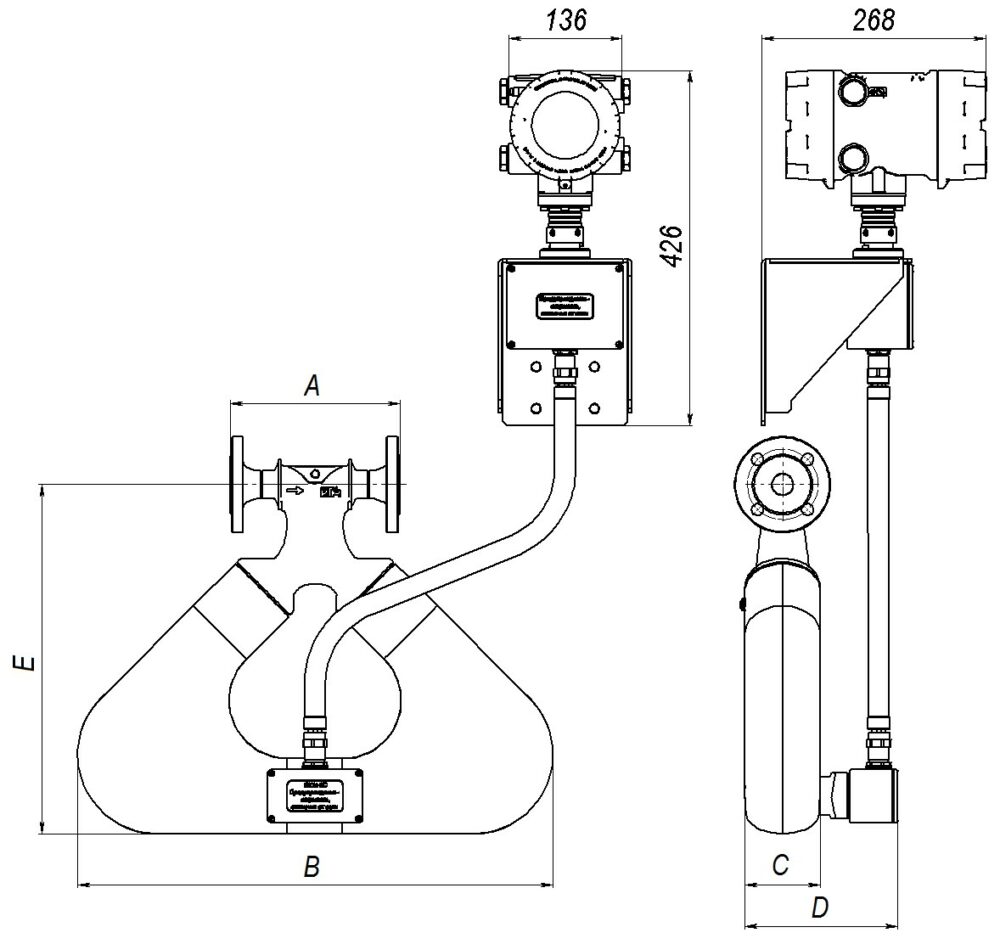

| a) KTM RuMASS E 050-250 integral design with BOI Lite |

b) KTM RuMASS E 050-250 integral design with standard BOI |

|

Overall dimensions of the Coriolis flow meter |

|||||||

|

Sizes |

Dimension A, mm |

Dimension B, mm |

Dimension C, mm |

Dimension D, mm |

Dimension E, mm |

Dimension F, mm |

|

|

BOI Lite |

Standard BOI |

||||||

|

KTM RuMASS E 050 |

543-708 * |

501 |

145 |

236 |

748 |

325 |

513 |

|

KTM RuMASS E 080 |

813-1108 * |

767 |

208 |

300 |

998 |

373 |

564 |

|

KTM RuMASS E 100 |

969-1406 * |

806 |

274 |

367 |

1019 |

439 |

627 |

|

KTM RuMASS E 200 |

992-1149 * |

806 |

324 |

416 |

1250 |

439 |

627 |

|

KTM RuMASS E 250 |

1030-1222 * |

806 |

354 |

446 |

1367 |

437 |

627 |

|

_______________ * Depending on flange design |

|

|

|||||