Flow Density Meter KTM Scalaris ®

Fluid density and temperature measurement with the possibility of mass flow rate, mass, volute flow rate, and fluid volume indication

Benefits:

- Metrologically assured measurement of medium parameters with density to 2000 kg/m³ with the function of compensation of readings by temperature and pressure;

- Medium flow metering channel with the error ±1%;

- Possibility of primary and/or periodic calibration only for density metering channels (at customer’s option);

- Maximum temperature of measured medium to 400°С;

- Maximum pressure of measured medium to 30 MPа;

- Service life – 20 years.

METROLOGY AND TECHNICAL CHARACTERISTICS

| Parameter name | Parameter value |

| Inside nominal diameter, mm | from 25 to 50 |

| Operating medium density measurement range, kg/m3 | from 650 to 2000 |

| Mass flow rate measurement range, kg/h | from 65 to 91700 |

| Operating medium temperature, °С: | from -60 to +400 |

| Operating medium excess pressure, MPa: | to 30 |

| Limit of density permissible fundamental absolute measurement error, kg/m3 | ±0,2; ±0,3;±0,5; ±1; ±10 |

| Limit of mass and volume fluid flow rate, fluid mass and volume relative measurement (calculation) error, % | ±1 |

| Limit of temperature permissible absolute measurement error, °С | ±1 |

| Temperature repeatability, °С | ±0,2 |

| Calibration interval, years | 1 |

| Ambient temperature, °С | from — 40 to + 60 |

| IP degree of protection according to GOST 14254 (IEC 60529) | IP66/67 |

| Electronic unit explosion-proof marking | 1Ex db e [ia Ga] IIC T6 Gb X |

| Measurement device housing explosion-proof marking | 0Ex ia IIC T6…T1 Ga X |

| Outputs and interfaces: | — frequency (time period signal TPS)/pulse output;

— analog configurable output, current loop with support of HART; — RS-485 with support of Modbus RTU and Modbus ASCII; — Ethernet with support of Modbus TCP; — analog input for temperature and pressure sensors, current loop with support of HART |

| Direct current power voltage, V | from 12 to 30 |

| Input power, W, not more than | 15 |

| Mean time to failure term, h, not less than | 150 000 |

| Service life, years | 20 |

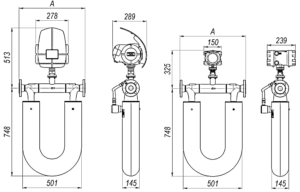

DENSITY METER OVERALL AND CONNECTION DIMENSIONS

KTM SCALARIS 50 Density Meter:

| а) | б) |

а) with the standard design IPU; b) with the Light design IPU

Flanges on KTM SCALARIS 50 of standard and cryogenic design

| Code | DN | PN | Standart | Flange type | Sealing surface type | A size, mm | Weight (with stand. IPU), kg, кг |

Weight (with Light IPU), kg, кг |

Weight (without IPU), kg), кг |

||||||||||

| 301 | DN40 | – | DIN 32676 | Hygienic fitting | – | 543 | 54 | 46 | 32 | ||||||||||

| 302 | 40mm | 10K | JIS B 2220 | Weld neck flange | Raised face | 548 | 58 | 49 | 36 | ||||||||||

| 311 | 40mm | 20K | JIS B 2220 | Weld neck flange | Raised face | 548 | 58 | 50 | 36 | ||||||||||

| 321 | DN40 | PN40 | GOST 33259 | 11 (butt weld) | B (joggle) | 561 | 59 | 50 | 37 | ||||||||||

| 322 | DN40 | PN40 | GOST 33259 | 11 (butt weld) | D (groove) | 561 | 58 | 50 | 36 | ||||||||||

| 323 | DN40 | PN40 | EN 1092-1 | Weld neck flange | Type B1 | 547 | 58 | 50 | 36 | ||||||||||

| 324 | DN40 | PN40 | EN 1092-1 | Weld neck flange | Type D | 547 | 58 | 50 | 36 | ||||||||||

| 325 | NPS1½ | CL150 | ASME B 16.5 | Weld neck flange | Raised face | 581 | 58 | 50 | 36 | ||||||||||

| 331 | NPS1½ | CL300 | ASME B 16.5 | Weld neck flange | Raised face | 594 | 60 | 52 | 38 | ||||||||||

| 341 | DN40 | PN100 | GOST 33259 | 11 (butt weld) | B (joggle) | 605 | 62 | 54 | 40 | ||||||||||

| 342 | DN40 | PN100 | GOST 33259 | 11 (butt weld) | D (groove) | 605 | 62 | 54 | 40 | ||||||||||

| 343 | DN40 | PN100 | EN 1092-1 | Weld neck flange | Type B1 | 580 | 62 | 54 | 40 | ||||||||||

| 344 | DN40 | PN100 | EN 1092-1 | Weld neck flange | Type D | 580 | 62 | 54 | 40 | ||||||||||

| 345 | NPS1½ | CL600 | ASME B 16.5 | Weld neck flange | Raised face | 605 | 61 | 53 | 39 | ||||||||||

| 401 | DN50 | – | DIN 32676 | Hygienic fitting | – | 543 | 54 | 46 | 32 | ||||||||||

| 421 | DN50 | PN40 | GOST 33259 | 11 (butt weld) | B (joggle) | 561 | 60 | 52 | 38 | ||||||||||

| 422 | DN50 | PN40 | GOST 33259 | 11 (butt weld) | D (groove) | 561 | 60 | 52 | 38 | ||||||||||

| 423 | DN50 | PN40 | EN 1092-1 | Weld neck flange | Type B1 | 553 | 60 | 52 | 38 | ||||||||||

| 424 | DN50 | PN40 | EN 1092-1 | Weld neck flange | Type D | 553 | 60 | 52 | 38 | ||||||||||

| 425 | NPS2 | CL150 | ASME B 16.5 | Weld neck flange | Raised face | 581 | 59 | 51 | 37 | ||||||||||

| 431 | NPS2 | CL300 | ASME B 16.5 | Weld neck flange | Raised face | 594 | 62 | 54 | 40 | ||||||||||

| 441 | DN50 | PN100 | GOST 33259 | 11 (butt weld) | B (joggle) | 607 | 66 | 58 | 44 | ||||||||||

| 442 | DN50 | PN100 | GOST 33259 | 11 (butt weld) | D (groove) | 607 | 66 | 58 | 44 | ||||||||||

| 443 | DN50 | PN100 | EN 1092-1 | Weld neck flange | Type B1 | 580 | 65 | 57 | 43 | ||||||||||

| 444 | DN50 | PN100 | EN 1092-1 | Weld neck flange | Type D | 580 | 65 | 57 | 43 | ||||||||||

| 445 | NPS2 | CL600 | ASME B 16.5 | Weld neck flange | Raised face | 600 | 63 | 55 | 41 | ||||||||||

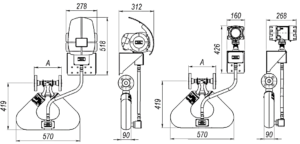

KTM SCALARIS 25 density meter:

| а) | б) |

а) with the standard design IPU; b) with the Light design IPU

Flanges on KTM SCALARIS 25 of standard and cryogenic design

| Code | DN | PN | Standart | Flange type | Sealing surface type | A size, mm | Weight (with stand. IPU), kg |

Weight (with Light IPU), kg, кг |

Weight (without IPU), kg |

| 201 | DN25 | – | DIN 32676 | Hygienic fitting | – | 213 | 43 | 35 | 17 |

| 202 | 25mm | 10K | JIS B 2220 | Weld neck flange | Raised face | 211 | 46 | 37 | 20 |

| 211 | 25mm | 20K | JIS B 2220 | Weld neck flange | Raised face | 211 | 46 | 38 | 20 |

| 221 | DN25 | PN40 | GOST 33259 | 11 (butt weld) | B (joggle) | 204 | 46 | 37 | 20 |

| 222 | DN25 | PN40 | GOST 33259 | 11 (butt weld) | D (groove) | 204 | 46 | 37 | 20 |

| 223 | DN25 | PN40 | EN 1092-1 | Weld neck flange | Type B1 | 211 | 46 | 37 | 20 |

| 224 | DN25 | PN40 | EN 1092-1 | Weld neck flange | Type D | 211 | 46 | 37 | 20 |

| 225 | NPS1 | CL150 | ASME B 16.5 | Weld neck flange | Raised face | 236 | 45 | 37 | 19 |

| 231 | NPS1 | CL300 | ASME B 16.5 | Weld neck flange | Raised face | 248 | 47 | 38 | 21 |

| 241 | DN25 | PN100 | GOST 33259 | 11 (butt weld) | B (joggle) | 244 | 48 | 40 | 22 |

| 242 | DN25 | PN100 | GOST 33259 | 11 (butt weld) | D (groove) | 244 | 48 | 40 | 22 |

| 243 | DN25 | PN100 | EN 1092-1 | Weld neck flange | Type B1 | 244 | 49 | 40 | 23 |

| 244 | DN25 | PN100 | EN 1092-1 | Weld neck flange | Type D | 244 | 49 | 40 | 23 |

| 245 | NPS1 | CL600 | ASME B 16.5 | Weld neck flange | Raised face | 260 | 47 | 39 | 21 |

| 341 | NPS1½ | CL600 | ASME B 16.5 | Weld neck flange | Raised face | 260 | 49 | 41 | 23 |