Averaging Pitot tube KTM Deltapascal ®

Cost reduction projects for power consumption and pumping equipment service life. Metering of steam, hot liquids and ultrahot smoke emissions

Benefits:

- Saving 5-15% on energy costs at the replacement of constriction devices with a Pitot tube due to pressure drop decrease from 20-30 % to 5-8 %;

- Increase of the steam turbine or pump service life and equipment life of 20% due to incoming pressure reduction;

- Reduction of expenses by 4 times for the flow meter assembly/disassembly, calibration, shipping costs, exchange fleet, no repair expenses;

- Integrated computing device in explosion-proof housing, ready for volume calculations without additional equipment;

- In-process assembly/disassembly;

- Simulation calibration;

- Temperature and pressure flow compensation;

- Metering on exhaust ducts of complex shape;

- Metering of high temperature gases to +710 °С to 25 MPa;

- Metering of air emissions on pipelines with diameters to 15 m;

- Calibration interval – 4 years, service life – 18 years.

METROLOGY AND TECHNICAL CHARACTERISTICS

| Parameter name | Parameter value |

| Nominal diameter of pipeline DN, mm | from 25 to 2950 |

| Measuring part material | AISI 316L / 03Х17Н14М3 |

| Volume flow rate measurement range, m³/h: | |

| — fluid | from 0,35 tо 358000 |

| — gas | from 0,7 tо 4,8∙10 6 |

| — steam | from 0,7 tо 6,9∙10 6 |

| Operating medium temperature, ºС | from — 196 tо + 710 |

| Operating medium excess pressure, MPa | tо 25 |

| Maximum pressure drop, kPа | 300 |

| Relative measurement error, % | |

| — of volume and mass flow rate | ±0,5; ±0,7; ±1,0; ±1,5 |

| — of volume and mass flow rate at simulation calibration | ±2,0 |

| Calibration interval, years | 4 |

| Ambient temperature, °С | from- 40 tо + 60 |

| IP degree of protection according to GOST 14254 (IEC 60529) | IP66/67 |

| IPU explosion-proof marking | 1Ex db e [ia Ga] IIC T6 Gb X |

| Outputs and interfaces: | — frequency (time period signal TPS)/pulse output;

— analog configurable output, current loop with support of HART; — RS-485 with support of Modbus RTU and Modbus ASCII; — Ethernet with support of Modbus TCP; — analog input for temperature and pressure sensors, current loop with support of HART |

| Direct current power voltage, V | from 12 to 30 |

| Input power, W, not more than | 15 |

| Mean time to failure term, h, not less than | 100 000 |

| Service life, years | 18 |

| Name | Appearance | Pressure | Temperature | Diameter |

|

By mounting on a pipeline |

||||

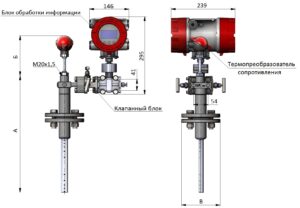

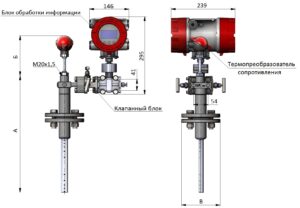

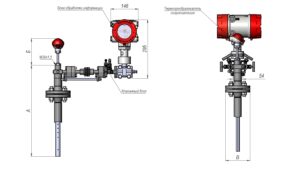

| Flange |  |

to 25 MPa | to +710 °С | To 2 950 mm (optionally to 15 000 mm) |

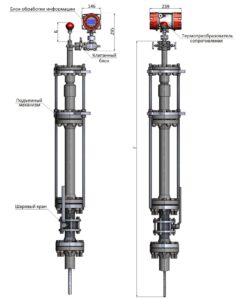

| Retractable |  |

to 10 MPa | +500 °С | to 1200 mm |

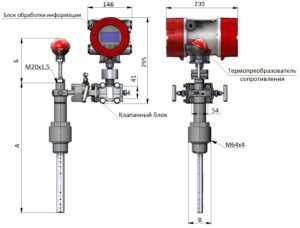

| Rotate-lock |  |

to 10 MPa | +500 °С | to 2950 mm |

|

By IPU location |

||||

| Integral |  |

to 25 MPa | +120 °С | to 2 950 mm (optionally to 15 000 mm) |

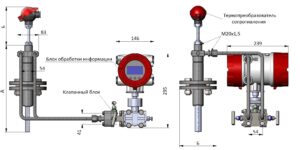

| Integral with dividing units (medium cooling units) |  |

+300 °С | ||

| Separate |  |

to +710 °С | ||

MEASUREMENT ELEMENT SIZE OPTIONS

| Measurement element width | Pipeline diameter | Diameter of a manifold for mounting |

| 8 mm | From 25 до 60 mm | 15 mm |

| 12 mm | From 50 to 150 mm | 20 mm |

| 25 mm | From 100 tо 800 mm | 32 mm |

| 44 mm | From 400 to 2950 mm (optionally to 15 000 mm) | 50 mm |

Video