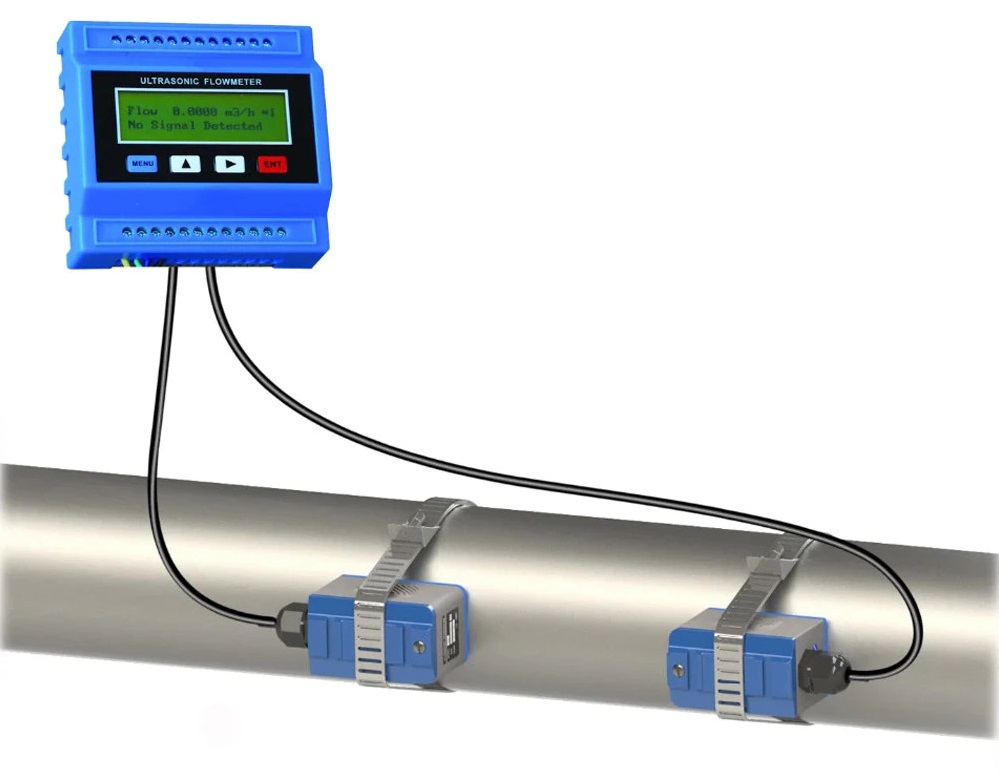

Ultrasonic clamp-on flow meters for gas and liquids are the portable devices for quick measurement of medium flow rate. Clamp-on transducers are simple to install on the pipe surface and it allows you to start measurement quickly. It is not necessary to insert the transducers into the pipe.

Ultrasonic liquid flow meters are used to measure the volume of liquid media that do not contain foreign inclusions.

Flow meters of this type are also called acoustic, since they function in the ultrasonic frequency range. The effect that occurs when sound vibrations pass through the fluid or gaseous flow is measured.

Portable ultrasonic flow meters make it possible to determine in which direction and at what speed the flow of gas or liquid moves through the pipeline.

Advantages of portable gas and liquid flow meters

Portable ultrasonic liquid and gas flowmeter is easy to use.

- Compact dimensions. You can easily move the device from place to place. Flow meters with additional elements are usually packed in small neat suitcases.

- Speed of measurement. No time to install the meter: in five minutes you can begin measurements.

- Contactless readings: sensors are applied to the pipe without interacting with liquid or gas.

- Wide range of measured media – water, chemicals, drug components, petroleum and petroleum products, food liquids and other substances.

- High measurement accuracy. Measurement error is – 0.5%.

- Connection of temperature and pressure sensors.

- Possibility of use in hard-to-reach areas.

- Relatively low cost.

Disadvantages of ultrasonic water and gas flow meters

A significant disadvantage of the ultrasonic portable meter is the need to monitor the operation of the device. Presence of service engineer is required. It is impossible to receive readings remotely.

Scope of application

The equipment is in demand in various industries: chemical, pharmaceutical, pulp and paper, food, aerospace, engineering, and so on, in research laboratories.

In heat supply systems, ultrasonic portable meter meters operate on both local and main pipelines. In air conditioning, they help track the starting or constant flow of ethylene glycol. In water supply, it is used to measure water – clean or unprepared. In drainage, mobile meters are used to measure storm, utility and drain drains.

In the manufacture of drugs, the absence of contact of a gas flowmeter or a portable liquid with a measured medium helps to maintain sterility. At concrete plants, overhead sensors allow accurate metering of concrete.

When auditing power grids, portable devices help to quickly determine the movement and consumption of energy. In housing and communal services, such devices make it possible to measure in parallel with stationary meters, which is necessary when resolving disputed issues with consumers.

The instrument is also used to monitor pump capacity.

It is advisable to buy a portable liquid flowmeter to detect losses and leaks of working medium on large pipeline networks with a large number of branches. When it is too expensive to install stationary meters on each branch, portable ultrasonic liquid flowmeters help to make measurements without significant costs. Two or three instruments are sufficient to regularly measure possible leaks and environmental losses in problem areas.

When do I use portable Meters?

It is recommended to buy a portable ultrasonic flowmeter for single or periodic measurements of working medium consumption during testing of process equipment, as well as in areas of the production chain where the installation of a stationary meter is not advisable.

Significant disadvantage

However, in many situations, a portable gas and liquid flow meter should prefer a stationary industrial model. This is necessary when you need to constantly monitor the flow rate of the environment. The ability to connect programmable relays to a stationary tie-in counter allows you to transmit signals to external equipment – dispensers, samplers, remote adders, alarms. In addition, not only ultrasound is used in in in-line flow meters. Devices with different operating principles are produced, which expands the possibilities of using devices.