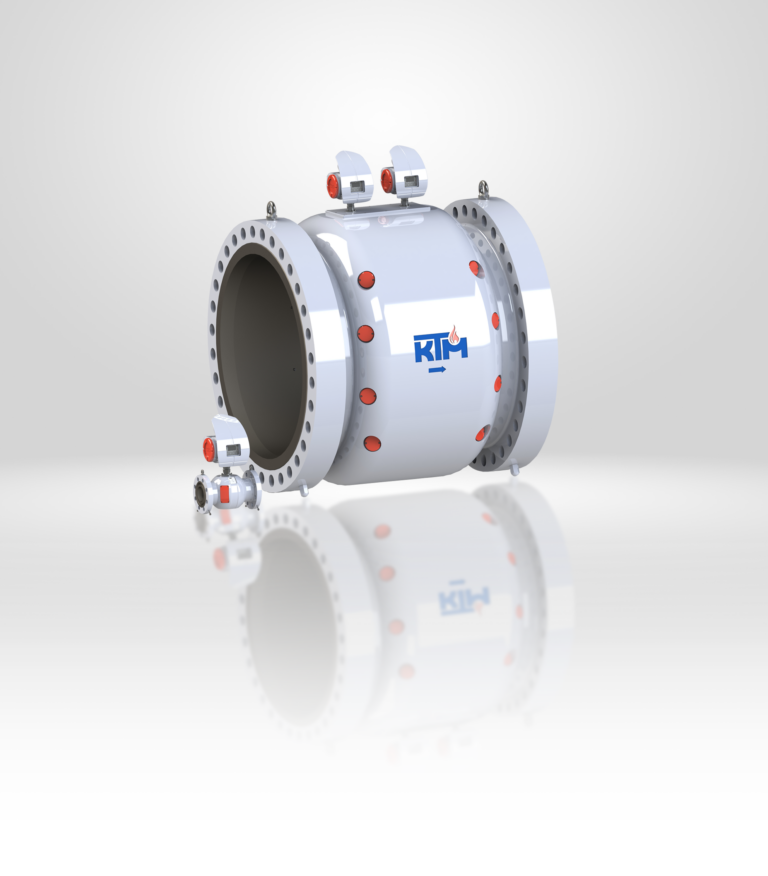

Ultrasonic Flow Meter KTM700 RUS ®

Commercial metering of natural gas, oil-dissolved gas and hydrogen

Benefits:

- Operating pressure (excess) to 45 МPа at turned solid design;

- Turned solid versions to DN1400;

- Metering of hydrogen H2 and pure gases;

- Metering of fume-laden and humid gases, gases with high content of mechanical impurities (UGS);

- Metering of corrosive gases (made from designated stainless steels: Monel*, Hastelloy** and other at customer’s request);

- Compensation of housing geometric dimesions change by temperature and pressure;

- Measurement error to ± 0.5%;

- Simulation calibration period ±0.7%;

- Calculation of gas mass flow rate without a density meter by “Hydrocarbon” method;

- Separate calculation for the Customer and the Consumer with two independent meters in one housing (Quadro version);

- CMC;

- Possibility of sensors replacement under operating pressure;

- Service life – 20 years.

* is a trademark owned by Special Metals Corporation

** is a trademark owned by Haynes International

METROLOGY AND TECHNICAL CHARACTERISTICS

| Parameter name | Parameter value | Remark |

| Inside diameter, mm |

from 50 tо 1400 |

|

| Lengths of straight sections |

5 х DN 10 х DN 20 х DN |

If an orifice box is available

After leadaway in 1 plane

After leadaway in 2 planes |

| Medium temperature, 0C |

-70 .. +180 |

Extended range: -194…+280 |

| Medium excess pressure, МPа |

from 0 to 28 |

Extended range: tо 45 |

| Untrasound sensors operation frequency, kHz |

80; 135; 200; 350 |

With deviation ±5% |

| Number of measurement channels | 2P (parallel arrangement)

2X (cross arrangement) 4 4×4 |

Quadro version |

| Limits of gas volume flow rate measurement relative error under operating conditions, % | ||

|

Qmin<Q<Qt |

±0.7* |

|

|

Qt<Q<Qmax |

±0.5 |

|

| Calibration interval, years |

4 |

|

| Number of information processing units (IPUs) |

1,2 * |

* — depending on a version |

| Ambient temperature, °С |

-40 ..+60 |

Extended range: -65…+65 with a thermal cover |

| IP degree of protection according to GOST 14254 (IEC 60529)

-Information processing unit with transmitter-receiver units; -Remote module |

IP66/IP67 IP54 |

|

| Explosion-proof marking |

1 Ex db eb ia [ia Ga] T6…T2 IIC Gb X |

|

| Outputs and interfaces |

— frequency (time period signal TPS)/pulse output; — analog configurable output, current loop with support of HART; — RS-485 with support of Modbus RTU and Modbus ASCII; — Ethernet with support of Modbus TCP; — analog input for temperature and pressure sensors, current loop with support of HART |

|

| Power voltage, V |

12…30 |

|

| Input power, W |

Not more than 6 |

|

| Mean time to failure term, h |

88000 |

|

| Service life, years |

20 |

Standard sizes and flow ranges

| Meter diameter | Gas flow rate in operating conditions m3/h | Gas velocity, m/s | |||

|---|---|---|---|---|---|

| Qmin | Qт | Qmax | Vt | Vmax | |

| DN80 | 5 | 40 | 1000 | 1.5 | 61 |

| DN100 | 8 | 65 | 1600 | 1.5 | 63 |

| DN150 | 16 | 100 | 3000 | 1.5 | 52 |

| DN200 | 20 | 160 | 4500 | 1.5 | 44 |

| DN250 | 25 | 240 | 7000 | 1.5 | 44 |

| DN300 | 35 | 310 | 8000 | 1.5 | 39 |

| DN350 | 45 | 420 | 10000 | 1.5 | 36 |

| DN400 | 60 | 550 | 14000 | 1.5 | 38 |

| DN450 | 100 | 700 | 17000 | 1.5 | 37 |

| DN500 | 130 | 850 | 20000 | 1.5 | 35 |

| DN550 | 150 | 1000 | 24000 | 1.5 | 35 |

| DN600 | 180 | 1200 | 32000 | 1.5 | 39 |

| DN650 | 240 | 1400 | 35000 | 1.5 | 36 |

| DN700 | 280 | 1700 | 40000 | 1.5 | 36 |

| DN750 | 320 | 1900 | 45000 | 1.5 | 35 |

| DN800 | 360 | 2200 | 50000 | 1.5 | 34 |

| DN850 | 400 | 2500 | 55000 | 1.5 | 33 |

| DN900 | 450 | 2800 | 66000 | 1.5 | 36 |

| DN950 | 500 | 3100 | 70000 | 1.5 | 34 |

| DN1000 | 550 | 3400 | 80000 | 1.5 | 35 |

| DN1050 | 600 | 3800 | 85000 | 1.5 | 34 |

| DN1100 | 650 | 4100 | 90000 | 1.5 | 32 |

| DN1150 | 700 | 4500 | 95000 | 1.5 | 34 |

| DN1200 | 750 | 4800 | 100000 | 1.5 | 30 |

| DN1300 | 900 | 5600 | 110000 | 1.5 | 28 |

| DN1400 | 1000 | 6500 | 120000 | 1.5 | 27 |

Notes:

Qmin – minimal flow rate;

Qmax — maximal flow rate;

Qt — limit flow rate;

Vmax — maximal gas velocity;

Vt — limit gas velocity.