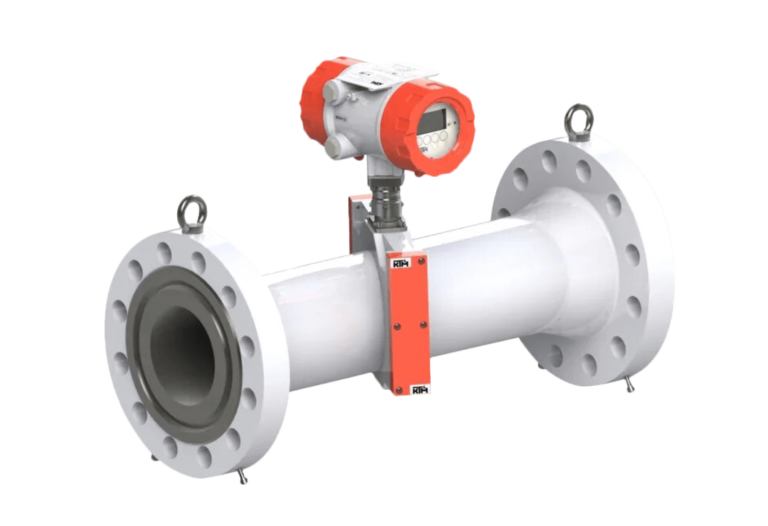

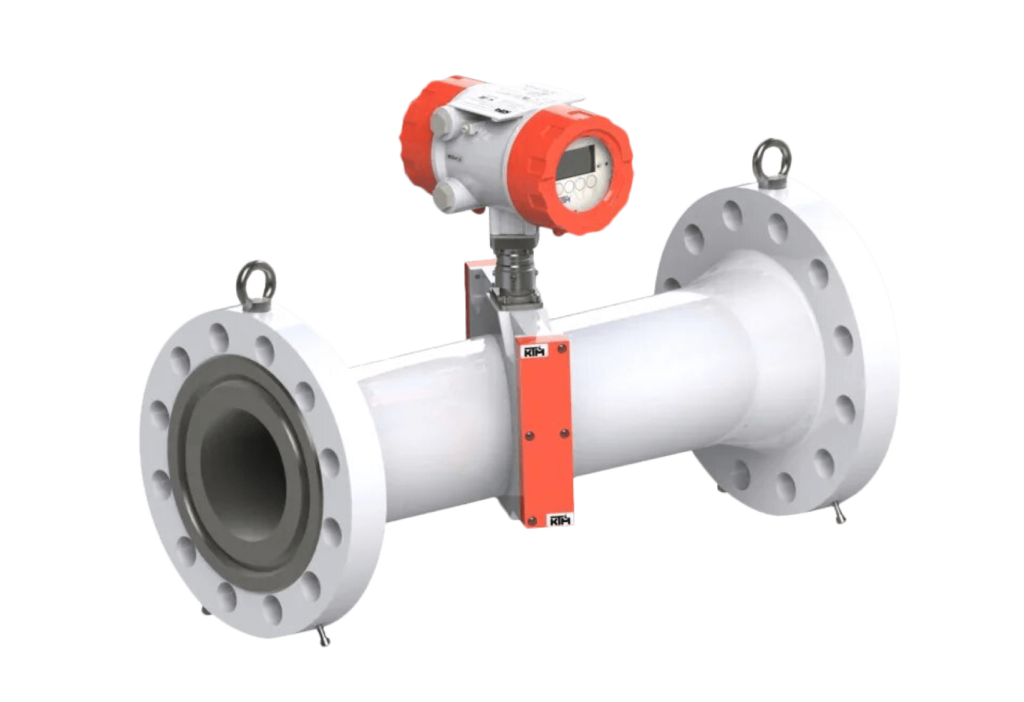

KTM600 RUS ®

About product

Ultrasonic flow meter for gas process applications measurements

Applications

- Natural gas and associated petroleum gas measurement

- Company gas consumption monitoring

- Measurement of gas in gas wells and plumes

- Measurement of gas lift

- As part of the gas measurement unit

- As part of the automated group metering unit

- Measurement of gas in underground gas storage facilities

- Measurement of natural gas, N2, O2, air, ethylene

- Measurement of gasses with high H2S component such as sour gas or biogas

- Onshore and offshore gas measurement applications

Your benefit

- Reliable and stable measurement due to the absence of reflected acoustics paths. Measurement data does not depend on inner pipe contamination or fouling.

- Robust design of the ultrasonic transducers ensures stable signal generation and reception in wet gas applications

- Properly selected operation frequencies of the transducers make them neutral to environmental noises.

- Real-time diagnostics of the meter operation and on-time feedback to the operator.

- Temperature and pressure changes are compensated by specialized algorithms based on experimental data.

- Meter can be calibrated in air at ambient pressure.

- Less need for systematic verification of the meter: once in 4 years using simple “Zero flow verification” method

- Service life – 15 years.

Technical details

| Parameter name | KTM600 RUS | Notes |

|---|---|---|

| Nominal pipe diameter (DN), mm | from 50 up to 1400 | |

| Ambient temperature, °С | -55… +60 | Extended range: -65…+65 using thermal cover |

| Gas temperature, °С | -40… 180 | Extended range: -194…280 |

| Storage temperature, °С | -40…+60 | |

| Operating pressure, bar | 0…280 | Extended range: Up to 450 |

| Number of measurement paths | 2Р (parallel paths) 2Х (cross paths) |

|

| Number of information processing units (IPU) | 1,2* | * – depends on version of de-vice |

| I/O signals and ports | RS-485 Ethernet Analog Digital |

ASCII RS-485/RTU RS-485

1 output: 4 … 20 mA |

| Enclosure rating – IPU and Sender-receiver units: – Remote interface module: |

IP66/IP67 IP54 |

|

| Supply voltage, V | 12…30 | |

| Power consumption, Wtt | Less than 6 |

Metrological parameters

| Parameter name | Error limit |

|---|---|

| Measuring ranges Volumetric flow a. c., % 2Р (parallel paths) 2Х (cross paths) |

±0,7 – 1 ±1,5 – 3 |

Nominal meter sizes and corresponding maximum flow rates

| Nominal meter diameter | Volume flow rate a.c. m3/h | Maximum gas velocity, m/s | ||

|---|---|---|---|---|

| DN | Qmin | Qт | Qmax | Vmax |

| 50 | 4 | 13 | 400 | 65 |

| 80 | 8 | 32 | 1000 | 65 |

| 100 | 13 | 50 | 1600 | 60 |

| 150 | 20 | 80 | 3000 | 50 |

| 200 | 32 | 130 | 4500 | 45 |

| 250 | 50 | 240 | 7000 | 40 |

| 300 | 65 | 375 | 8000 | 33 |

| 350 | 80 | 375 | 10000 | 33 |

| 400 | 120 | 600 | 14000 | 33 |

| 450 | 130 | 650 | 17000 | 33 |

| 500 | 200 | 975 | 20000 | 33 |

| 600 | 320 | 1500 | 32000 | 33 |

| 700 | 400 | 2000 | 40000 | 30 |

| 750 | 400 | 2000 | 45000 | 30 |

| 800 | 400 | 2400 | 50000 | 30 |

| 900 | 650 | 3750 | 66000 | 30 |

| 1000 | 650 | 5000 | 80000 | 30 |

| 1050 | 1300 | 6000 | 85000 | 30 |

| 1100 | 1400 | 6500 | 90000 | 28 |

| 1200 | 1600 | 7000 | 100000 | 27 |

| 1300 | 2000 | 7300 | 110000 | 26 |

| 1400 | 2300 | 8600 | 130000 | 25 |